KC metal recycler moves into new HQ, ready for 'next level' growth

By Leslie Collins – Specials editor, Kansas City Business Journal

The 50-year-old metal recycler is profitable and thriving, but it wants more. A new headquarters is only part of that plan.

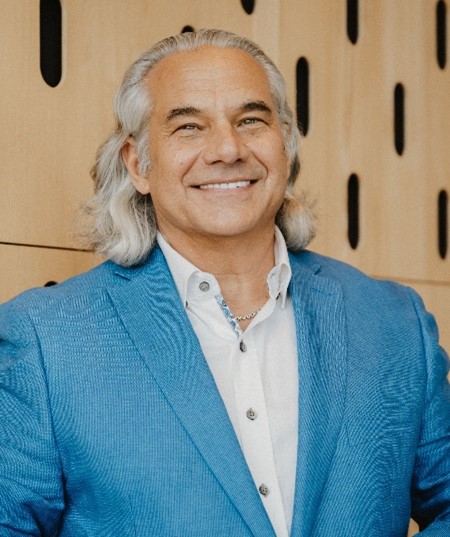

Scrap Management Industries’ next chapter isn’t a turnaround story. The 50-year-old ferrous and non-ferrous metal recycler is profitable and thriving. But it wants a transformation, CFO Keith Rhodes said.

“I’m taking a profitable company and trying to position it to maximize its growth,” he said.

That’s why the Burgess family hired him. They want him to take the roughly 300-person company to the “next level,” he said. Locally, it employs about 145.

SCRAP MANAGEMENT INDUSTRIES

Rhodes joined the Kansas City-based business in 2021. Since then, he’s brought on key talent to cultivate growth, including a vice president of non-ferrous and a vice president of finance. The company scouted a new headquarters in the East Crossroads at 1741 McGee St., which also happens to house one of its customers: Clarkson Construction Co.

Scrap Management Industries' previous headquarters was housed in double-wide trailers in an industrial area at 8116 Wilson Road in Kansas City. It wasn’t conducive for hiring administrative and other corporate-level roles, Rhodes said.

“We just felt like this area was a better professional representation of where we were going,” he said.

Where the company is headed is expansion. It has facilities in Kansas, Missouri and Oklahoma, but it wants to extend its reach in those states and branch out into surrounding states.

“We are actively working on a few different acquisitions to grow the business,” he said. “We’re continually improving our processes and our systems.”

It recently made a sizable investment, for example, at its Oklahoma City location, adding an automobile shredder.

The company also is taking a more proactive approach with brand awareness and hired Kansas City-based EAG Advertising & Marketing as its agency of record to the lead the charge on billboard, radio and digital advertising campaigns.

“We’re letting people know we’re there, rather than just kind of word of mouth,” Rhodes said.

Since hiring the vice president of non-ferrous, the company seized new opportunities and started selling non-ferrous metal overseas in places such as China, Vietnam, India and Pakistan, which expands its customer base and helps it balance supply and demand.

Scrap Management Industries is the fourth scrap company that Rhodes has worked for where he’s been tasked with catapulting growth. One previous company had eight yards when he started, and had 50 a decade later.

Scrap Management Industries moved into its 10,000-square-foot headquarters last year, but still was adding finishing touches, so it hosted a ribbon-cutting ceremony last month. It signed a 10-year lease, with options to renew. The space features artful photos of the metals it recycles and a glass conference table has been transformed into an art piece, showcasing physical displays of common products that are processed at its facilities. Rhodes devised the idea. He also wanted TVs to scroll through photos of the company’s operations.

“People don’t really understand our business all that well, because it’s one of those hidden businesses that’s behind the scenes," he said. "People don’t think about, ‘What do you do with a pile of stuff like that?’”

The company serves a variety of customers: Think companies that need metal to remelt for products such as cars, refrigerators, sheet metal, copper pipe and rebar in concrete.

“We don’t actually melt anything. We’re packaging the materials to fit their recipe for their furnaces,” Rhodes said.

It’s like making a cake, he said. Each recipe calls for different ingredients and bowl sizes.

“You have to look at their specifications, their chemistries, and then you have to understand what metal you’re getting and the alloys, and separate it, process it and package it,” he said. “We’re always looking for innovative technology to help us be more cost-effective and efficiently separate metals and prevent less material from having to be landfilled.”